What is a Shear Wall?

A shear wall is a structural element typically made of reinforced concrete, masonry, or other materials that provides lateral resistance to forces acting on a building, such as wind loads or seismic (earthquake) forces. Shear walls are crucial for the stability and safety of structures, particularly in regions prone to earthquakes and high winds.

Key features of shear walls include:

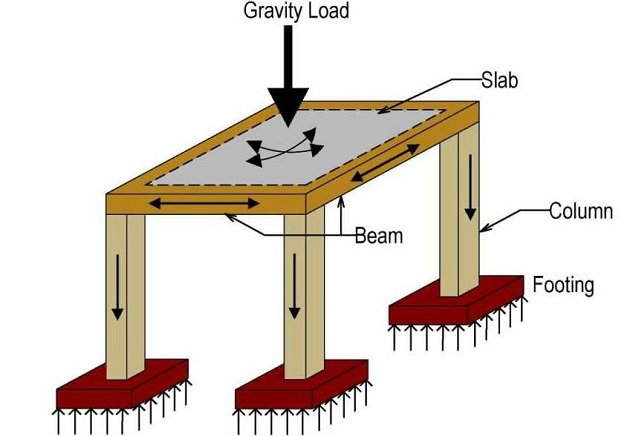

1. Lateral Load Resistance: Shear walls are designed to resist lateral forces that can cause a building to sway or deform horizontally. These forces may be caused by wind blowing against the structure or the ground shaking during an earthquake.

2. Vertical Orientation: Shear walls are usually vertical elements integrated into the building’s structural framework. They can be located on the building’s exterior or interior, depending on the design.

3. High-Strength Construction: Shear walls are constructed using materials with high compressive and shear strength. Reinforced concrete and masonry are common choices due to their ability to withstand lateral forces.

4. Anchoring: Shear walls are securely anchored to the foundation to ensure that they can effectively transfer lateral forces to the ground.

5. Openings and Reinforcements: Openings for doors, windows, and other building components are carefully planned in shear walls to maintain their structural integrity. Additional reinforcement, such as steel bars, may be added to enhance their strength.

6. Distribution of Forces: Shear walls distribute lateral forces across their length and transfer them to the building’s foundation, preventing excessive swaying or deformation.

When Are Shear Walls Required?

Shear walls are typically required in areas susceptible to high winds and earthquakes. In such regions, most buildings, including homes, need exterior shear walls for added structural stability. Additionally, larger houses and tall buildings often require interior shear walls to further safeguard against lateral forces from wind and seismic activity. These shear walls play a crucial role in preventing structural damage and ensuring the safety of occupants during adverse weather conditions and seismic events.

How Do Shear Walls Work?

Shear walls are designed to withstand specific forces that act on them, and they can fail in several ways due to these forces. The main forces and corresponding failure modes are as follows:

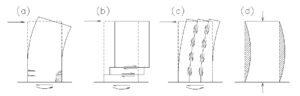

Failure mechanisms of shear walls: (a) flexural failure, (b) horizontal shear, (c) vertical shear, (d) buckling.

1. In-Plane Shear: Shear walls experience lateral forces that induce in-plane shear stresses. This means that the shear wall is subject to horizontal forces trying to push it in one direction.

2. Flexure: In addition to shear, shear walls also experience bending forces due to moments created by shear. This results in flexural stresses that act along the plane of the shear wall.

3. Vertical Shear: Shear walls also resist in-plane shear forces in the vertical direction, which is a direct consequence of the horizontal shear forces they experience. This ensures stability in both horizontal and vertical directions.

4. Buckling: Shear walls may be susceptible to buckling due to dead loads acting from the top. Buckling is a failure mode where the shear wall bends out of its plane under the influence of compressive loads.

SHEAR WALL: TYPES

Shear walls come in various types, each designed to fulfill specific structural requirements and architectural considerations. The choice of shear wall type depends on factors such as building design, loading conditions, material availability, and construction methods. Here are some common types of shear walls:

1. Reinforced Concrete Shear Walls: These are typically constructed using reinforced concrete and are widely used in high-rise buildings and structures subjected to seismic forces. Reinforced concrete shear walls provide excellent strength, stiffness, and ductility, making them effective in resisting lateral loads. They are often designed as solid walls or with openings strategically placed and reinforced.

2. Masonry Shear Walls: Masonry shear walls are constructed using brick, concrete block, or stone masonry. They offer good resistance to lateral loads and are commonly used in low- to mid-rise buildings. Masonry shear walls may be solid or contain reinforced concrete or steel elements to enhance their strength and ductility. Proper construction techniques and detailing are essential to ensure the stability and integrity of masonry shear walls.

3. Steel Plate Shear Walls (SPSW): Steel plate shear walls consist of vertical steel plates or panels attached to the building frame to resist lateral loads. They are commonly used in steel-framed buildings and offer advantages such as high strength-to-weight ratio, flexibility in design, and ease of construction. Steel plate shear walls can be configured as either unstiffened or stiffened systems, depending on structural requirements.

4. Prefabricated Shear Wall Systems: Prefabricated shear wall systems are manufactured off-site and then assembled or installed on-site. These systems may include precast concrete panels, steel plate assemblies, or engineered wood panels with integrated reinforcement. Prefabricated shear wall systems offer benefits such as faster construction, improved quality control, and reduced labor costs.

5. Cross-Laminated Timber (CLT) Shear Walls: CLT shear walls consist of cross-laminated timber panels connected to the building frame to resist lateral loads. CLT panels are made by gluing together multiple layers of wood in alternating directions, providing strength, stiffness, and dimensional stability. CLT shear walls are lightweight, sustainable, and increasingly used in mid-rise and high-rise timber buildings.

6. Braced Frames: While not technically shear walls, braced frames are structural systems consisting of diagonal braces or trusses designed to resist lateral loads through tension and compression forces. Braced frames are commonly used in steel and timber-framed buildings and are effective in providing lateral stability while minimizing the impact on floor layouts and architectural design.